What ever do I mean, don’t lose your bearings?

Do I think everyone is lost? No not exactly, not even close…

I actually, mean don’t lose your bearings.

Now you may be lost…

What is he talking about?

Let me reintroduce myself: I am the Go Kart Guru. I am a specialist in go kart design, fabrication and development. I help people make high quality homemade go karts. On go karts there are bearings. Bearings on drive shafts, axels, engines, and wheels. Make more sense now?

Back to losing our bearings…

I am specifically addressing here front wheel bearings.

In short there are good bearings and cruddy bearings.

You can literally “lose” your bearings and end up with a just a bearing race and no bearings at all, and a wheel on the ground. Not a good situation to be in.

I just had a reader write in and say he lost his front bearing and needed some advice. That prompted this article.

The following bearings are used on light duty applications, such as wheel barrows and hand carts. Unfortunately, you will find them frequently on lighter gocarts.

These bearings are basically a pressed metal shell with a hardened inner race. The outer shell is a thin formed sheet of steel that has little if no strength.

In fact the design of these bearings is for vertical loading, not side loading. The sides of the bearings will blow out with side loading.

These type bearings are not suited for go karts, because they cannot handle the side loading that occurs during cornering. They will last approximately 2 to 3 hours and then you will end up with a wheel coming off.

Diagram of Pressed Metal Bearing. The second picture shows a side load on the bearing causing the side to blow out.

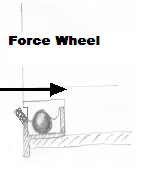

The type of bearing that should be used is a flange roller bearing. There are several types:

- Flanged roller bearing with the outer casing machined

- Flanged roller bearing with a snap ring on the outside

The most cost effective version is the snap ring style because all that is required in the machining process is to cut a groove versus taking off a whole chunk of material to make the flange.

Picture of a "snap ring" flanged bearing. Used on a front wheel. Note the double nuts are designe to keep the nut system from tightening and crushing the bearing system. The other side, is purpose is the opposite, to keep the nuts from unwinding and the wheel falling off!

The downside to using the flange style bearings is that most off the shelf go kart spindles are 3/4ths in diameter (.75 inches).

This is a down side, because the “pressed metal” bearings are designed to run easily on the ¾ spindles. The OD of the “pressed metal” bearing fits easily inside the hub. The reason for this design is that the bearings inside the “pressed metal” style are extremely small and the inside bearing hub needs to be larger to make up the room.

What does that mean for the go karter who wants to use flanged bearings?

The typical flange bearing ID is .625, not .75 inches. The spindles that you get either have to be custom ordered, or buy the ¾ inchers and alter them to be .625 inches.

Picture of a modified "redone" spindel system. If you look real close you will see two bolt heads. The larger head served as a platform to weld the smaller .625 bolt onto.

If you are designing a go kart, keep this in mind that you get the correct spindle sizes, or you may end up “Losing your bearings” and you may actually end up on the trail: lost with no back up.

And one final word of advice: if you do chose to use the “pressed metal bearings” be sure to get at least 4 back ups to start with. At $4 dollars a pop, you may want to just invest in a $9 dollar bearing that will never fail.

GKG

Visit

GoKartGuru.com and take advantage of the information that is provided both in

video and

pdf form….